How the sensor works

Senior lead researcher Dr Nitu Syed said the sensor featured atomically thin transparent tin dioxide that can easily track ammonia at much smaller levels than similar technologies.

“Our device acts like an electric ‘nose’ by efficiently detecting even the tiniest amount of ammonia,” said Syed, McKenzie Research Fellow from the University of Melbourne, RMIT and TMOS.

“The sensor is also able to distinguish ammonia from other gases with more selectivity than other technologies.”

The presence of ammonia in the air changes the electrical resistance of the tin oxide film in the sensor: the higher the level of ammonia, the greater the change in the resistance of the device.

The team conducted experiments with their sensor in a specially designed chamber to test its ability to detect ammonia gas at various concentrations (5 – 500 parts per million) under different conditions, including temperature. They also tested the device’s selectivity of ammonia against other gases, including carbon dioxide and methane.

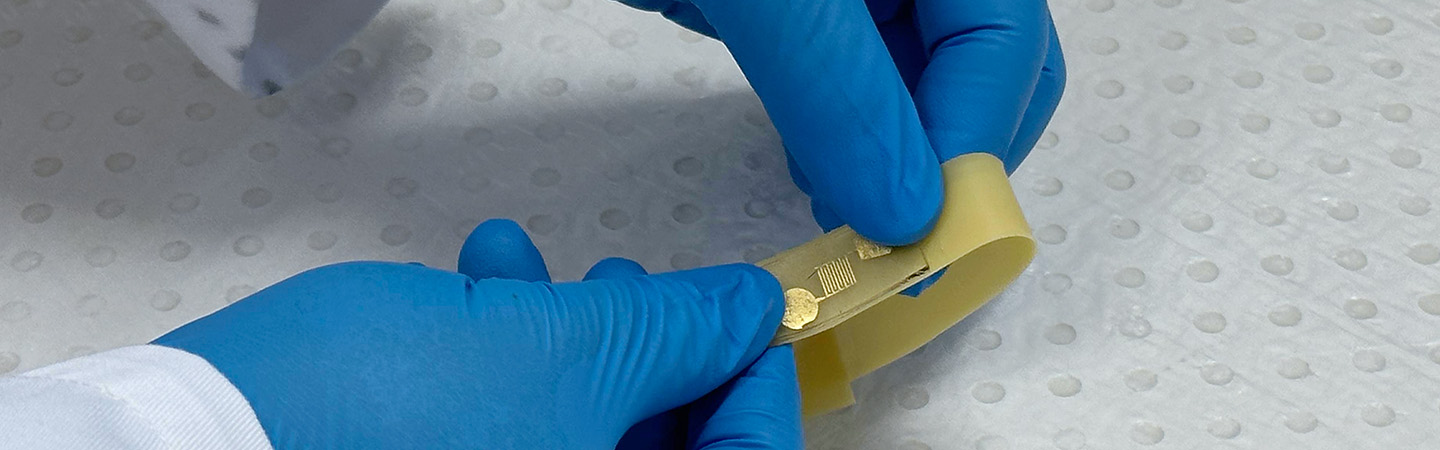

First author, Dr Chung K. Nguyen from RMIT, said their miniaturised sensor offered a safer and less cumbersome way to detect the toxic gas, compared to existing techniques.

“Current approaches to ammonia detection produce accurate measurements but require expensive laboratory equipment with qualified technicians, extensive sampling and preparation,” Nguyen said.

“This process is often time-consuming and not portable, due to the size of the equipment needed. In addition, the manufacturing of today’s ammonia detectors involves expensive and complicated processes to prepare sensitive layers for sensor fabrication.”

The team’s new sensor can instantaneously differentiate between safe and dangerous levels of ammonia in the environment, Nguyen said.

“The reproducible deposition of tin oxide also offers the opportunity for cost-effective mass production of sensing devices,” he said.